Publication

from The American Oil Chemists' Society

by Marie Wong, Cecilia Requejo-Jackman, and Allan Woolf

What is unrefined, extra virgin cold-pressed avocado oil?

The high oil content of the avocado fruit (Persea americana

Mill.) has been known since Aztec times, with the fruit sometimes

referred to as "vegetable butter" or "butter pear." The plant

originated in Central America, and its cultivation has spread to warm

subtropical and temperate climates worldwide. The flesh of an avocado

can contain up to 30% oil (based on fresh weight), but there is very

little in the seed (≈2%) or the skin (≈7%). Avocado oil was originally,

and still is, extracted for cosmetic use because of its very high skin

penetration and rapid absorption. Following pre-drying of the avocado

flesh to remove as much water as possible (≈65% water in avocado

flesh), avocado oil for cosmetics is traditionally extracted with

solvents at elevated temperatures. After extraction, the oil for

application in skin care products is usually refined, bleached, and

deodorized, resulting in an odorless yellow oil.

Avocados are primarily grown for the fresh fruit market, either

domestic or export. There are 12 major cultivars of avocado, but the

main cultivars grown globally are ‘Hass' and ‘Fuerte.' The ‘Hass'

cultivar constitutes more than 90% of the avocado crop in New Zealand

(NZ) as this cultivar has excellent yield potential and also suffers

less postharvest and handling disorders owing to their thicker skins.

In 2000, two processing companies in NZ began production of extra

virgin avocado oil; they pioneered the process for extracting

cold-pressed avocado oil, which is sold as culinary oil for use on

salads and for cooking (Eyres et al., 2001). Like extra virgin olive

oil, cold-pressed avocado oil is unrefined and so retains the flavor

and color characteristics of the fruit flesh.

Production levels

in NZ vary year to year depending on the season (some trees bear fruit

biennially), weather (wind and storms can damage fruit, which are then

not suitable for fresh fruit export), and export markets. Over the

2008/2009 season, NZ processors produced more than 150,000 liters of

extra virgin avocado oil, with production expected to increase in the

2009/2010 season. Extra virgin avocado oil is also being produced in

Chile, South Africa, and Kenya. Extra virgin avocado oil from NZ is

exported to Australia, Japan, Southeast Asia, Europe, and North America

by Grove Avocado Oil (Tauranga, NZ) and Olivado (Kerikeri, NZ).

Avocados are primarily grown in NZ for fresh fruit export; any fruit

not suitable for export is sold on the local market or to processors

(for oil and other processed avocado products). Approximately 3% of the

NZ avocado crop is processed for the oil. Windfall fruit not suitable

for the local market is sometimes bought by oil processors. Fruits that

are rotten or exhibit postharvest disorders and are unsuitable for

consumption are not used for oil production.

The process

developed in NZ for extraction of avocado oil is based on the

mechanical extraction method used for olive oil. However, before we

discuss the extraction process, we need first to consider the avocado

fruit and its development. It is important to understand the pre- and

postharvest physiology of avocados, particularly how their maturity and

degree of ripeness impact the optimum time for oil extraction.

Cultivation of avocado

Avocados

are grown in frost-free subtropical regions. Once the fruit has formed

on the tree, it slowly matures (10 months), increasing in size and oil

content. Most avocado-exporting countries have guidelines for when to

harvest the fruit such that they are considered to be at optimum

maturity to ensure they ripen and develop the desirable flavor and

texture profile. The maturity of avocados is easily determined by

measuring the dry matter content of the fruit (e.g., for NZ, the

minimum dry matter for export is 24% by fresh weight; for the United

States, it is 20.8%). The dry matter content is highly correlated with

the total oil content in the fruit, hence harvesting at less than the

minimum recommended dry matter content level will result in fruit with

less than optimal oil content. The correlation between dry matter and

oil content has been found to be valid across a number of countries

(NZ, Australia, and United States), with different regions and orchards.

Avocado

fruit do not ripen while they remain on the tree even once they have

reached maximum maturity. If the fruits are not harvested, they can

remain on the tree even when the next year's fruit is developing, and

can remain on the tree for more than 18 months from flowering. Once

harvested, the avocado will begin to ripen. This process involves the

softening of the flesh due to endogenous pectolytic enzyme activity

and, for some varieties, the coloring of the skin from green to

purple-black. The degree of ripeness of the avocado is primarily

determined by measuring the firmness of the fruit. Hence to ensure the

oil content in the avocados is at the maximum for processing, the fruit

should ideally be mature at harvest. This is not the case with immature

fruit blown off the tree in a storm (windfall fruit); this fruit is

still ripened but the oil content in the fruit is less than optimum.

Ripening leads to tissue softening, which aids with the extraction of

the oil due to the release of the oil from the parenchyma cells.

Ripening can be promoted by treating the fruit with ethylene (a gaseous

plant hormone that synchronizes ripening) in controlled-temperature

rooms.

To have optimal oil quality, avocado fruit should not be

overripe and also should have minimal rots or other postharvest

disorders (such as flesh greying due to long storage). The amount of

oil extracted from mature and ripe avocados earlier in the season has

been found to be only approximately 75% of the maximum available oil in

the flesh (15% oil by fresh weight) compared to later in the season

when it is possible to extract more than 90% of the available oil, this

being the maximum oil yield (≈25% oil by fresh weight).

EXTRACTION OF AVOCADO OIL

The

process for recovering oil from ripe avocados is a mechanical

extraction, similar to olive oil extraction, with the additional step

of removing the skin and stone (seed). After this, the flesh is ground

to a paste and then malaxed for 40-60 minutes at 45-50°C. This is a

higher malaxing temperature than used for olive oil extraction, but it

is still considered to be cold-pressed extraction for avocado oil. The

slightly higher temperature aids the extraction of the oil from the

oil-containing cells and does not affect the quality of the oil. The

oil and water phases are separated from the pulp using a high-speed

decanting centrifuge, and then the oil is separated from the water in

final polishing centrifuges. The pulp from the decanting centrifuge and

waste skin/seeds are returned to orchards for soil conditioning and

mulch, or used as animal feed.

Avocado oil, if extracted from

sound fruit (no rots, physiological disorders, or damage), will result

in oil with a very low percentage of free fatty acids (%FFA) (<0.5%

as oleic acid). Also, the peroxide values (PV) can be very low (<2

meq/kg). Recommended standards for extra virgin avocado oil have

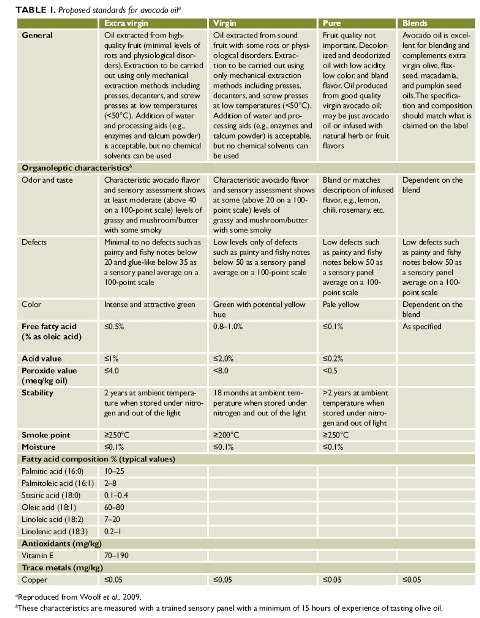

proposed a maximum PV of 4 meq/kg (Table 1).

In sound, ripened

fruit, the level of lipolysis that occurs is low, resulting in low

%FFA. The fruit does not need to be processed immediately after

ripening, but long delays should be avoided. Generally a higher %FFA is

due to poor-quality fruit, delays in processing ripened fruit, or poor

manufacturing practices.

PROPERTIES OF AVOCADO OIL

Extra

virgin avocado oil from the ‘Hass' cultivar has a characteristic

flavor, is high in monounsaturated fatty acids, and has a high smoke

point (≥250°C), making it a good oil for frying. ‘Hass' cold-pressed

avocado oil is a brilliant emerald green when extracted; the color is

attributed to high levels of chlorophylls and carotenoids extracted

into the oil.

Cold-pressed ‘Hass' avocado oil has been described

as having an avocado flavor, with grassy and butter/mushroom-like

flavors. Other varieties may produce oils of slightly different flavor

profile as has been seen with ‘Fuerte,' which has been described as

having more mushroom and less avocado flavor.

The fatty acid

profile is very similar to olive oil, in that it is very high in oleic

acid. A typical avocado oil has 76% monounsaturates (oleic and

palmitoleic acids), 12% polyunsaturates (linoleic and linolenic acids),

and 12% saturates (palmitic and stearic acids); these values are given

as percentage of fatty acid/total fatty acids. The main antioxidant in

the oil is a-tocopherol, which is present at levels of 70-190 mg/kg

oil. b-, g-, and d-tocopherols are only present in minor amounts

(<10 mg/kg oil). Other nonlipid components present in the oil

include chlorophylls (11-19 mg/kg oil) and carotenoids (1.0-3.5 mg/kg

oil).

The chlorophylls from the flesh and the skin contribute to

the characteristic emerald green color of the oil. Depending on the

location in the mesocarp, the chlorophyll content varies, but the

majority of chlorophyll and carotenoids are present in the greener

layers of flesh next to the skin. If avocado skin is included in the

pulp during malaxing, then the likelihood of extracting more pigments

is greater. Chlorophyll does not contribute to oil stability but can be

a problem, as chlorophyll can act as a sensitizer for photo-oxidation

to occur. Therefore, it is important to store the oil away from light.

Carotenoids

in avocado fruit have long attracted attention for their potential

anti-carcinogenic effect; these same carotenoids are subsequently

extracted into the oil. The most significant carotenoid present in the

oil is lutein (0.5-3.3 mg/kg oil). Lutein is beneficial for eye health

by reducing the progression of age-related macular degeneration. The

cold-pressed avocado oil also contains high levels of phytosterols

(b-sitosterol being the main sterol present), at 2.23-4.48 mg/g oil.

Based on its fatty acid makeup and the presence of these

phytochemicals, extra virgin cold-pressed avocado oil is considered to

be a healthful oil.

STANDARDS FOR AVOCADO OIL

The impacts

of postharvest procedures, preprocessing treatments, extraction, and

storage on the composition, quality, and sensory characteristics of

avocado oil have been investigated over the last 10 years in NZ in

collaboration with Australian and Californian research groups.

Standards have been proposed for avocado oil, including extra virgin,

virgin, and pure grades of oil (Table 1). These standards have been

recommended to ensure that avocado oil sold is of good quality in terms

of standard quality indices, composition, and sensory properties. The

standards are unique to avocado oil, where cold-pressed avocado oil is

recovered by mechanical extraction at temperatures less than 50°C,

without solvents; water and enzymes can be used. These standards are

important, as the production and culinary consumption of cold-pressed

avocado oil, with its light, distinctive flavor, is increasing

worldwide.

Marie

Wong is senior lecturer at the Institute of Food, Nutrition & Human

Health, Massey University (Auckland, New Zealand). She can be contacted

via email at M.Wong@massey.ac.nz . Allan Woolf and Cecilia

Requejo-Jackman are with the New Zealand Institute for Plant & Food

Research Limited (Auckland, New Zealand).

For further reading:

Eyres, L., L. Sherpa, and G. Hendriks, Avocado oil: A new edible oil from Australasia, Lipid Technology 13:84-88 (2001).

Woolf,

A., M. Wong, L. Eyres, T. McGhie, C. Lund, S. Olsson, Y. Wang, C.

Bulley, M. Wang, E. Friel, and C. Requejo-Jackman, Avocado oil. From

cosmetic to culinary oil, in Gourmet and Health-Promoting Specialty

Oils, R. Moreau and A. Kamal-Eldin, eds., AOCS Press, Urbana, Illinois,

USA, 2009, pp. 73-125.

|

|